CE Medical Compressed Air Systems Oil Free Vertical Stationary Type

-

High Light

CE Medical Compressed Air Systems

,Medical Compressed Air Systems Stationary Type

,oxygen compressor plant AC Power

-

Lubrication StyleOil-free

-

Cooling SystemAir Cooling

-

Power SourceAC Power

-

Cylinder PositionVertical

-

Structure TypeClosed Type

-

Installation TypeStationary Type

-

WarrantyWooden Case

-

Place of OriginBeiJing

-

Brand Namecape golden

-

CertificationCE ISO

-

Model NumberCACA-25

-

Minimum Order Quantity1

-

Delivery Time40 day

-

Payment TermsL/C, D/A, D/P, T/T, Western Union, MoneyGram

CE Medical Compressed Air Systems Oil Free Vertical Stationary Type

Medical Air Compressed System with Ce

Product Description

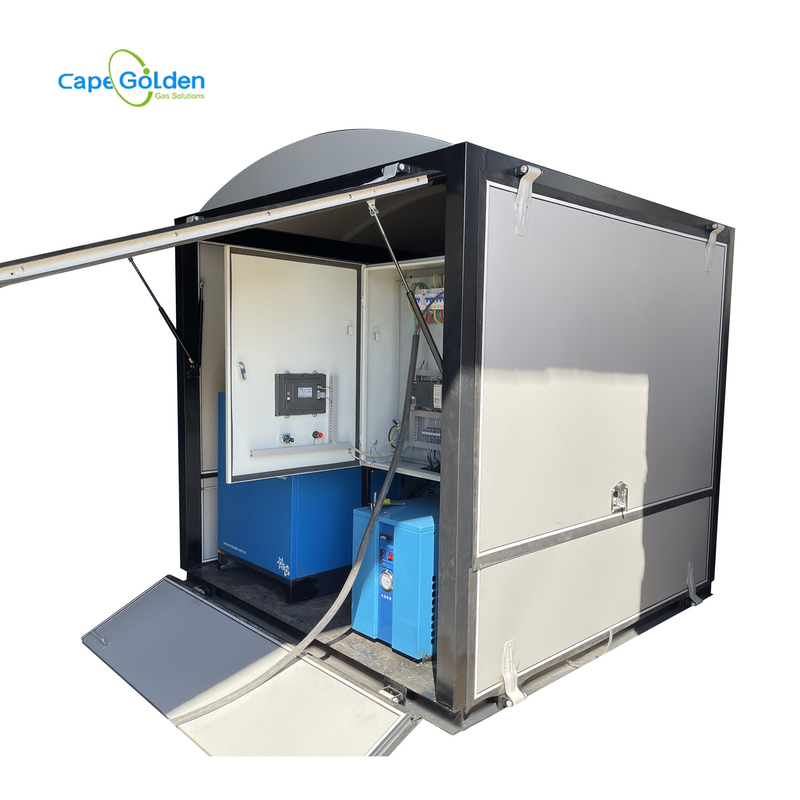

Medical compressed air system provides power source for part of pneumatic medical equipment in hospital, which is mainly composed of electric control box, pressure alarm, air compressor, air storage tank, filter, cold and dry machine, pipe fittings and air terminal.

The air passes through the compressor, the volume becomes smaller, the pressure is higher, and it is transported to the gas storage tank, which reduces the flow rate and settles some water, oil and dust particles. At the same time, it can store gas and compensate for consumption. Compressed air precision filter can filter the compressed air oil, water, dust particles, impurities and odor, the filtering accuracy can reach 0.01μm. After filtering compressed air into the dryer, no heat regeneration adsorption dryer can remove the moisture in the compressed air, reduce the dew point of the compressed air to -70℃. The purified air is decompressed through the pressure reducing valve, output to each medical unit through the compressed air pipeline, and each medical unit is redistributed to the medical compressed air terminal.

Medical Air Compressor System, like medical oxygen and suction, is an important part of the centralized air supply system in modern hospitals.

It is mainly used in the following:

1. The power of ventilator in intensive care unit and emergency room.

2. Provide oxygen/air mixture to patients, especially those with severe illness.

3. Power as pneumatic tools in the operating room.

4. Power as a dental pneumatic tool.

5. The power for some equipment in the supply room.

6. The power of physical therapy and rehabilitation equipment.

Usually, for larger hospitals with a scale of 500-1000 beds, three (or two) oil-free air compressors with a gas supply of 1.5-2.0m3/min, can meet the gas needs of about 40

![]()