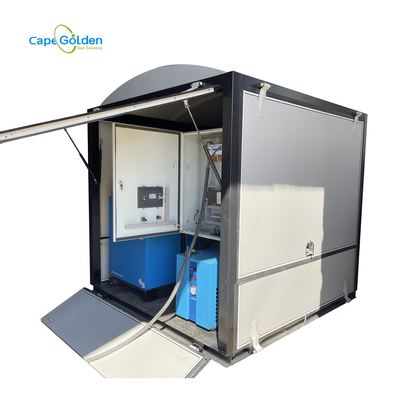

Containerized type Oxygen Generator for filling cylinders

Cape-Golden Oxygen Generator Concentrator Systems offer an endless supply of Oxygen for a wide range of commercial applications.

For more than 10 years, Cape-Golden has manufactured Oxygen Generator Concentrator in purity from 90% to 99%. Our rugged and reliable Oxygen Generator Concentrator are precision-tuned and ideally suited for a range of commercial applications.

Absorption is the physical process of separating molecules. Our Pressure Swing Adsorption (PSA) oxygen generation systems generate oxygen by separating it from the nitrogen in ordinary air. Air is 20.9% oxygen and 79% nitrogen, along with a small percentage of inert gases.

Within our Oxygen Generator Concentrator, a vessel containing a molecular sieve called zeolite is filled with compressed air. The nitrogen molecules are adsorbed by the sieve material while the oxygen molecules drift past and are collected in an oxygen receiver tank attached to the oxygen generator.

Pressure is then released from the vessel, and the nitrogen molecules are vented to the atmosphere. While the depressurization is occurring, the cycle is repeated in a second vessel. The process is repeated swinging from one vessel to another for as long as there is an oxygen demand.

* All components are oxygen-compatible

* Produce oxygen from compressed air

* Microprocessor controlled

* Low operating cost

* Automatic and unattended operation

* Easy to install and maintain

|

|

|

|

CAOG-3

|

Capacity: 3nm3/h, 12 Cylinders per Day (24 Hours)

|

|

CAOG-5

|

Capacity: 5nm3/h, 20 Cylinders per Day (24 Hours)

|

|

CAOG-10

|

Capacity: 10nm3/h, 40 Cylinders per Day (24 Hours)

|

|

CAOG-15

|

Capacity: 15nm3/h, 60Cylinders per Day (24 Hours)

|

|

CAOG-20

|

Capacity: 20nm3/h, 80 Cylinders per Day (24 Hours)

|

|

CAOG-25

|

Capacity: 25nm3/h, 100 Cylinders per Day (24 Hours)

|

|

CAOG-30

|

Capacity: 30nm3/h, 120 Cylinders per Day (24 Hours)

|

|

CAOG-40

|

Capacity: 40nm3/h, 160 Cylinders per Day (24 Hours)

|

|

CAOG-50

|

Capacity: 50nm3/h, 200 Cylinders per Day (24 Hours)

|

|

CAOG-100

|

Capacity: 100nm3/h, 400 Cylinders per Day (24 Hours)

|

|

Remark: Cylinder volume is 40Liters, 150bar.

|